Institute of Powder Metallurgy

Functional Powder Materials Laboratory

【Laboratory Introduction】

The Functional Powder Materials Laboratory belongs to the Institute of Powder Metallurgy, University of Science and Technology Beijing, with five teachers. The main research directions include powder injection molding, aluminium nitride ceramics, refractory metals and superalloys, preparation and application of new nano-powder materials, hydrogen storage materials and applications, lithium-ion batteries and materials, high energy density BiSb liquid metal battery materials, and so on. In recent years, the research laboratory had undertaken more than 50 national and provincial-level scientific research projects including the National Natural Science Foundation, the National Key Research and Development Program, the National 973 Program, the National 863 Program, the New Century Excellent Talent Support Program of the Ministry of Education, and the National Defense Military Industry. The research laboratory has published more than 200 SCI papers in many industry authoritative magazines, such as J. Mater. Chem. A., ACS Appl. Mater. Inter., Chem Commun, Carbon, J. Am. Ceram. Soc., Powder Technol., Int. J. Refract. Met. H. J. Magn. Magn. Mater., J. Power. Sources., J. Phys. Chem. C. etc, and have authorized more than 100 invention patents. Research laboratory have got two first prize and one second prize of Excellent Achievements Award (Technology Invention Award) of the Ministry of Education, two first prize and one second prize of China's non-ferrous metal industrial technology invention, one second prize of Beijing science and technology, and one second prize of Shandong province science and technology.

【Team members introduction】

|

|

|

|

|

Qin Mingli |

Li Ping |

Jia Baorui |

Wu Haoyang |

An Fuqiang |

Qin Mingli Professor, doctoral supervisor

Li Ping Professor, doctoral supervisor

Jia Baorui Assistant Professor

Wu Haoyang Postdoctoral faculty

An Fuqiang Postdoctoral faculty

【Research interest and achievements】

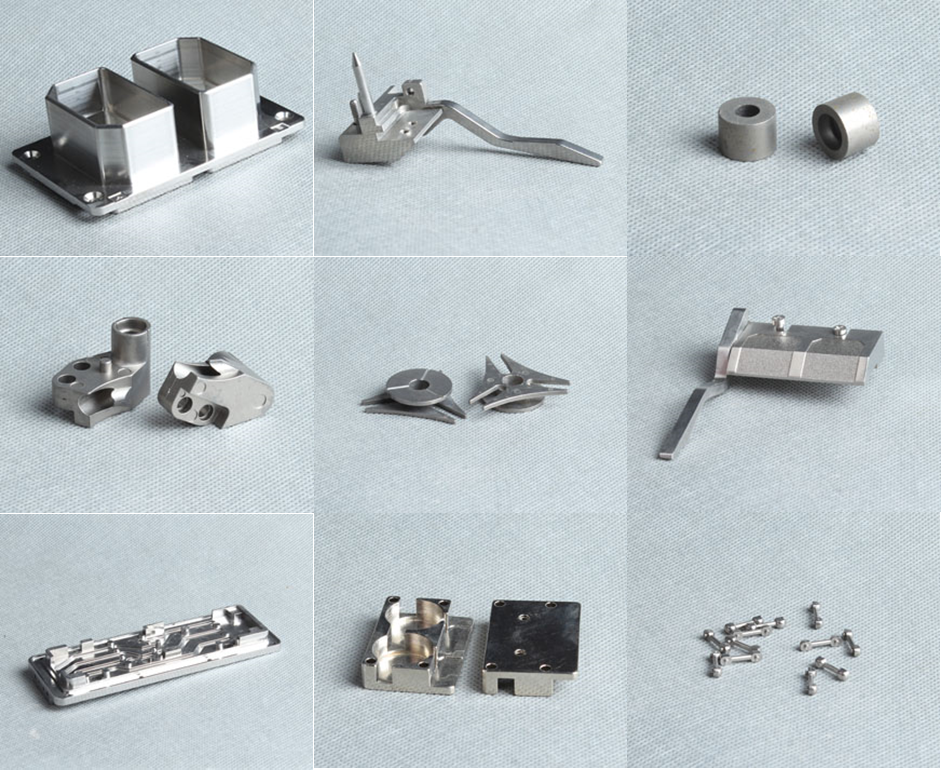

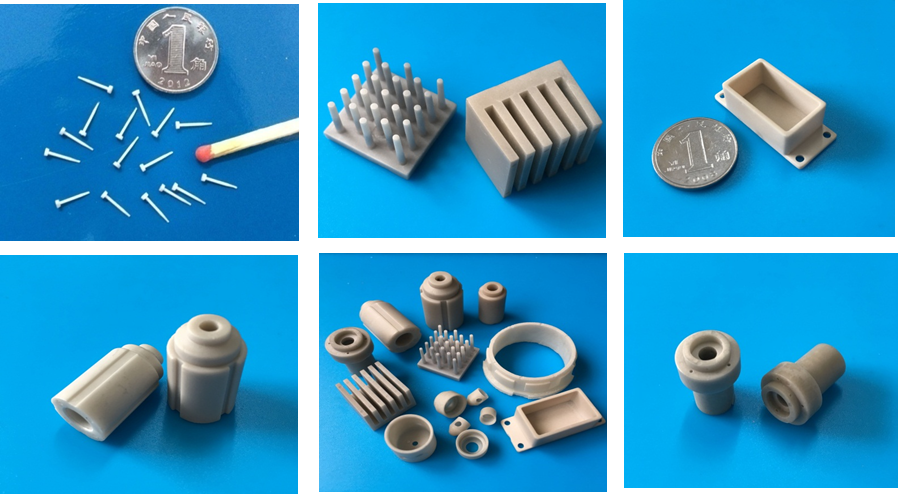

1、Powder Injection Molding Technology and Its Application

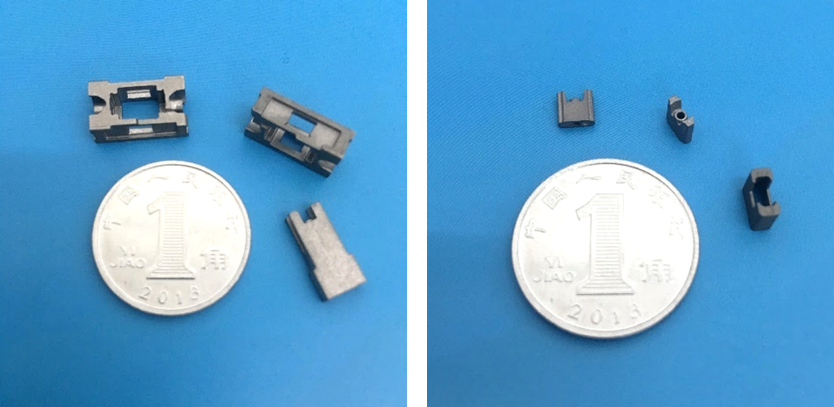

Powder injection molding (PIM) is a near net shape technology which is formed by introducing modern plastic injection molding technology into the powder metallurgy. In this technology, granulates raw material powder and binding material can be mixed by using binder as carrier for plastic injection, then sintered at high temperature after removed the binder there was the final product. Applying this technology can not only produce precise parts in large quantities at low cost, but also solve some difficult problems in the preparation of complex shaped products with high performance and difficult-to-process materials. It is called a revolution of parts processing and manufacturing technology. Focusing on the key problems of the development and application of this technology, we have carried out further basic theory and application research, and achieved many innovative achievements in the preparation principle and process of injection moulding powder, the design of binder, the strengthening sintering and the regulation of micro-structure, etc. Powder injection moulding (PIM) technology for aluminum nitride, metal soft magnet, refractory metal, superalloy, titanium alloy, high nitrogen stainless steel and other material systems have been established. It has been successfully applied in many important types of national defense weapons and civilian products and achieved remarkable social and economic benefits. Relevant research has won three first- prize awards and one second prize award for provincial and ministerial scientific and technological achievements, published more than 100 papers and authorized more than 50 invention patents.

The developed partial injection molded products

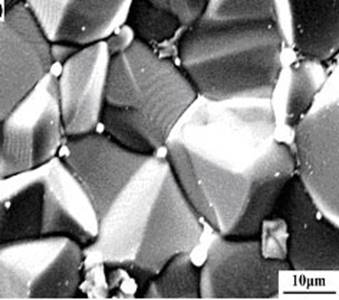

2、Research and Application of Aluminum Nitride Ceramics

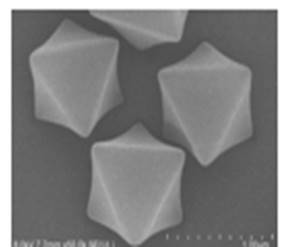

Aluminum nitride, with the characteristics of high heat conduction, low expansion, insulation and high modulus of elasticity, is often used as the key material in military electronics, aerospace and other fields. The preparation and precision molding technology of high-quality aluminium nitride powder were established. High-purity and fine-grained aluminium nitride powder was developed. Its total content of metal impurities was less than 50 ppm, the oxygen content was 0.7-0.8 wt% and the average particle size was about 1 micron. The powder injection moulding technology of aluminium nitride had been developed, which solved the problem that complex shape products could not be directly processed due to its high hardness and brittleness, and realized the precision manufacturing of aluminium nitride products. The thermal conductivity of aluminium nitride products reaches 248 W.m-1K-1. Various aluminium nitride products developed had been successfully used in aerospace, naval ships, Electronics and other fields. Relevant researches have been published more than 20 papers in J. Am. Ceram. Soc, J. Eur. Ceram. Soc, Ceram. Intel, CrystEngComm, ACS Appl. Mater. Inter, Carbon, etc. and have been conferred 16 invention patents, the research results are awarded the First Prize for Technical Invention of China's Nonferrous Metals Industry (Precision Molding Technology and Application of High Thermal Conductivity Aluminum Nitride).

Aluminum nitride powder Organization of aluminum nitride products

The developed partial aluminum nitride products

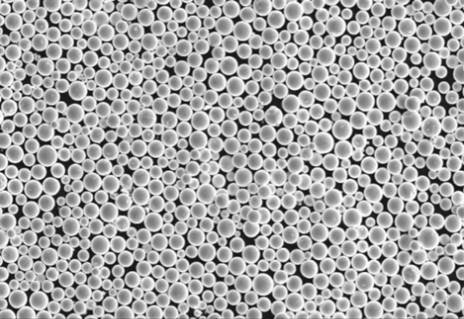

3、Refractory metals and alloys

Metal tungsten is the metal with the highest melting point and lowest vapor pressure, high density, low coefficient of thermal expansion, high temperature resistance, resistance to electron bombardment. It plays an irreplaceable role in the modern national defense, atomic energy, electric vacuum and some special high temperature application field. The preparation of complex tungsten products with a density of more than 95% and a grain size of about 500nm was carried out by solution combustion synthesis of nanometer tungsten-based powder and its near final molding technology. A new method of preparing fine spherical tungsten powder was developed by combining the dispersion classification of tungsten powder with plasma spheroidization. A variety of tungsten products were successfully applied in electronics, nuclear energy, aerospace and other fields. More than 30 papers about these relevant achievements have been published in Int. J. Refract. Met. H., Design, Mater. Lett., And these research achievements have applied for more than 20 national invention patents and authorized 18. They have won the first prize of “Excellent Achievements in Scientific Research (Techological Invention) of the Ministry of Education in Colleges and Universities”.

Spherical tungsten powder microstructure of ultrafine grain tungsten products

The developed partial tungsten products

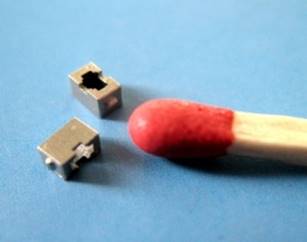

4、Metal Soft Magnetism by Powder Injection Molding and Enhanced Sintering

Metal soft magnetic materials (Fe-Ni, Fe-Co, Fe, etc.) with high permeability and low coercivity are indispensable basic materials in the fields of electronics, electricity, communications, automobiles and medical equipment. The technology of powder injection moulding and intensified sintering for metal soft magnetism had been established, and realized the high efficiency and low cost near net shape manufacturing of complex and precise soft magnetic parts. It not only overcomes the shortcomings of wasting resources and high manufacturing cost in machining process, but also solves the problem of low density and magnetic properties of traditional powder metallurgy soft magnetic materials. And its performance "reach "the best level in the world" (conclusion of appraisal of scientific and technological achievements). A variety of metal soft magnetic products had been produced to meet the needs of the development of national defense weapons and related industries. Relevant achievements have been published about 12 SCI papers in J. Magn. Magn. Mater., Powder Technol., J. Alloy Compd. etc. And these research achievements have applied for more than more than 16 national invention patents and 10 authorizations. They have won the first prize for technological invention of China's non-ferrous metal industry (near-net shape manufacturing technology for high performance metal soft magnetic products).

Fe-Ni alloy yoke for moving iron unit

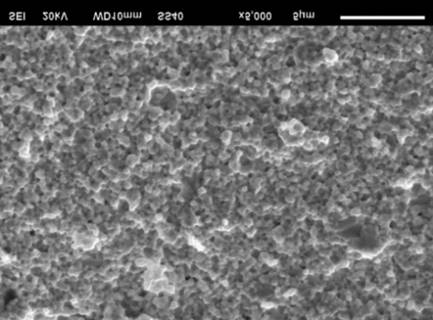

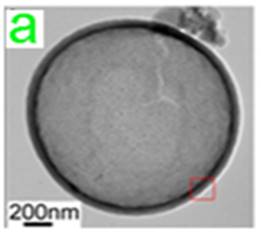

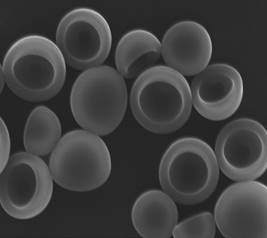

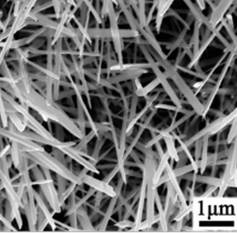

5、Preparation and application of new nano powder materials

Research on new technology and application of nano powder material was carried out. New nanometer powders are prepared by means of physical and chemical methods such as solution combustion, hydrothermal and plasma. By adjusting reaction parameters, nano powder materials with controllable particle size, morphology and phase were synthesized, which were applied in powder metallurgy, environment, energy, catalysis and other fields. Relevant achievements have been published 25 SCI papers in J. mater. Chem. A., ACS appl. Mater. Inter., chem. Commun., carbon and other magazines. And these research achievements have applied for more than more than 20 national invention patents and 10 authorizations.

a variety of nano powder materials

6、Hydrogen storage materials and application

Hydrogen storage materials are a kind of materials that can reversibly absorb and release hydrogen, and are used in the fields of hydrogen storage, hydrogen recovery, and heat storage. (1) Hydrogen storage: Toyota Mirai is a model of hydrogen energy application, with a hydrogenation mileage of 630 km in 3 minutes. Hydrogen storage is one of the key links of hydrogen energy utilization; solid hydrogen storage has the advantages of large hydrogen storage capacity and safety. (2) Hydrogen recovery: The hydrogen-rich tail gas is recovered by the selective absorption of hydrogen by hydrogen storage materials; it has the advantages of high purity, long cycle life and good safety. (3) Heat storage: Solar heat collection requires heat storage; hydrogen storage material is used for heat storage, and the heat storage density is 30 times that of molten salt. It can be recycled thousands of times and has good safety.

Devices for Hydrogen Storage Recycling of H2 Thermal Energy Storage

7、Electrode materials and devices for Alkali-metal ion battery

With lithium-ion battery as the core, researches on its material end, electrode end and application end are carried out. Through the organic combination of model and experiment, a bridge combining theory and engineering from raw material to cell design is constructed.

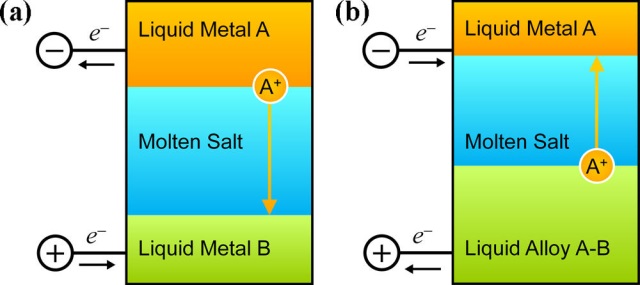

8、Materials and system for Liquid metal battery

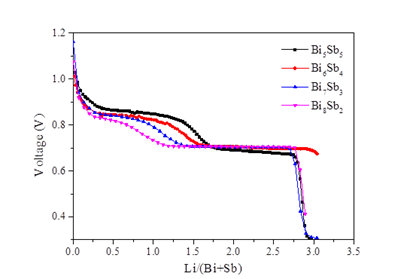

Liquid metal batteries have excellent high-rate performance, low cost and long life, and can be used for energy storage in the grid. The research and development of BiSb alloys has the highest energy density.

Principles of Liquid metal battery Performance of BiSb-based Liquid metal battery

【Research projects】

In recent years, the research laboratory had undertaken more than 50 national and provincial-level scientific research projects including the National Natural Science Foundation, the National Key Research and Development Program, the National 973 Program, the National 863 Program, the New Century Excellent Talent Support Program of the Ministry of Education, and the National Defense Military Industry. Part of items as follows:

1. National key research and development plan: the preparation technology of large-size high-purity rare metal products, RMB 22.21 million, 2017-2021; the key preparation technology development and demonstration application of large-scale high-performance iron and alloy alloy; RMB 25.8 million,2017-2021; preparation and industrialization of copper alloy gate sheet, RMB 1.2375 million,2016-2020.

2. National Natural Science Foundation of China: study on the Synthesis of Nano-tungsten Carbide (WC) based Powder by carbothermal reduction Combustion precursor, 600000, 2018-2021; low temperature Combustion Synthesis of rare Earth oxide doped Tungstate based Powder, 756000, 2016-2019; study on the process and Mechanism of preparing Hollow carbon Ball by Emulsion hydrothermal Carburization, RMB 200000, 2016-2019; Research on the basic problems of polymer/hydrogen storage alloy composites for hydrogen recovery, RMB 400000, 2015-2019; basic problems related to near net forming of high thermal conductivity aluminum nitride (AlN) ceramics, RMB 600000, 2012-2015; study on low temperature combustion synthesis of non-oxide ceramic powder, RMB 200000, 2009-2011.

3. National 973 Plan: the near-final form of the powder and the precise control of the tissue, RMB 3.75 million,2006-2010.

4. National 863 Program: advanced preparation Technology of High performance Powder Metallurgy Materials and their components, RMB 28.57 million, 2013-2016; Refractory Metal based Composite cathode Materials Development and component Molding Technology-High Power Microwave strong Field Materials, RMB 2.95 million, 2012-2015; key preparation Technology and Application Development of New rare Earth hydrogen Storage Materials, RMB 200000, 2011-2013; double connected structure SiCp/Al Composites and their near final forming Technology, RMB 1 million, 2006-2010; High capacity nanocrystal-amorphous magnesium based composite hydrogen storage materials for fuel cells prepared by special process, RMB 500000, 2006-2009.

5. Ministry of Education Outstanding talents support Program for the New Century: near final forming and organizational Precision Control of Tungsten cathode substrate, RMB 500000, 2010-2010.

6. New Metal National Key Laboratory Project:Study on Mechanism of Cyclic Stability of High Capacity RE-Mg-Ni System A2B7 Hydrogen Storage Electrode Alloy,200,000,2012-2013。

7. Defence military industry projects: more than 10 items, the topic is slightly, the total funding is about 30 million.

8. Factory association project: more than 10 items, the topic is slightly, the total funding is about 10 million.

9. Huo Yingdong Education Foundation Higher Education Teacher Fund: Research on mold manufacturing technology for large-scale production of large parts, 20,000 dollars, 2011-2012

10. Beijing Natural Science Foundation: Research on low-temperature combustion synthesis of nano-vanadium carbide powder, 100,000, 2018-2019; process and formation mechanism of hollow carbon spheres synthesized by emulsion hydrothermal carbonization, 100,000, 2017-2018; solution combustion synthesis nano Tungsten-based powder material, 180,000; 2016~2018; mechanism of ferrite catalyst on thermodynamics and kinetics of NaAlH4-MgH2 hydrogen storage material, 180,000, 2015-2017; research on solution combustion synthesis of aluminum nitride powder, 110,000, 2011-2012.

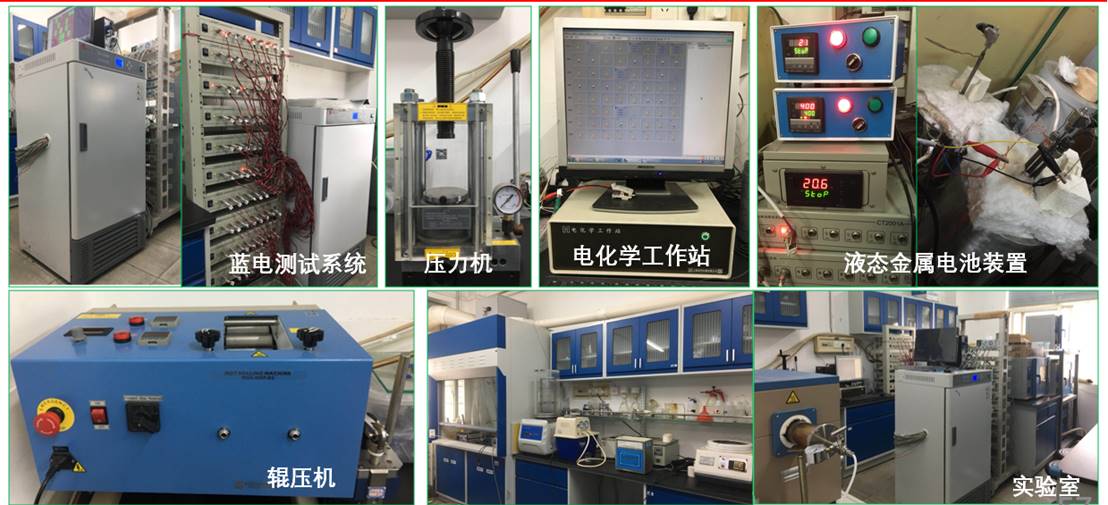

【Equipment】

HVC high speed press molding machine 3D printing and molding machine (Germany SLM125)

SPS discharge plasma sintering furnace injection molding machine

Vacuum degreasing/sintering furnace (Japan) hot isostatic pressing furnace

Kilogram hydrogen storage/heat storage system Hydrogen storage material PCT curve test equipment