Institute of corrosion control systems engineering

Corrosion Integrated Computing and Evaluation Laboratory

【General introduction of the laboratory】

There are 4 staff in the Corrosion Integrated Computing and Evaluation Laboratory. The main research directions are: material atmospheric corrosion and protection, corrosion simulation calculation and experimental verification, microstructure and corrosion behavior, rapid corrosion evaluation methods and techniques, material/device corrosion life assessment, biomedical materials and corrosion resistant materials. The research staff is responsible for more than 50 projects of the Ministry of Science and Technology, the National Natural Science Foundation and the industrial research projects. We has won two second prizes for national scientific and technological progress, and many research achievements have won provincial and ministerial-level scientific and technological progress awards. We has developed a series of corrosion test devices with independent intellectual property rights, and a large number of research results have been promoted and applied in enterprises.

【Staff】

|

|

||

Chaofang Dong |

Yunhua Huang |

Kui Xiao |

Xuequn Cheng |

Chaofang Dong Professor,Doctoral supervisor |

Yunhua Huang Professor,Doctoral supervisor |

Kui Xiao Professor,Doctoral supervisor |

Xuequn Cheng Professor,Master supervisor |

【Main research and Achievements】

(1) Corrosion simulation calculation and experimental verification: cross-scale corrosion damage simulation, pitting calculation and electrochemical verification, design and calculation of corrosion resistant materials;

(2) Microstructure and corrosion behavior: in-situ electrochemical study of local corrosion, mechanism of action of inclusions and precipitation relative corrosion, optimization of preparation process of corrosion resistant alloys;

(3) High reliability and rapid corrosion evaluation methods and techniques: correlation between indoor and outdoor atmospheric corrosion test and acceleration ratio research, accelerated environmental spectrum formulation and selection, real-time, in-situ monitoring technology;

(4) Material/Device Corrosion Life Assessment: Electronic Information Materials/Device Failure Mechanisms in Complex Environments, Corrosion Safety Assessment and Life Assessment of Passive Metal Components.

Achievements

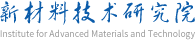

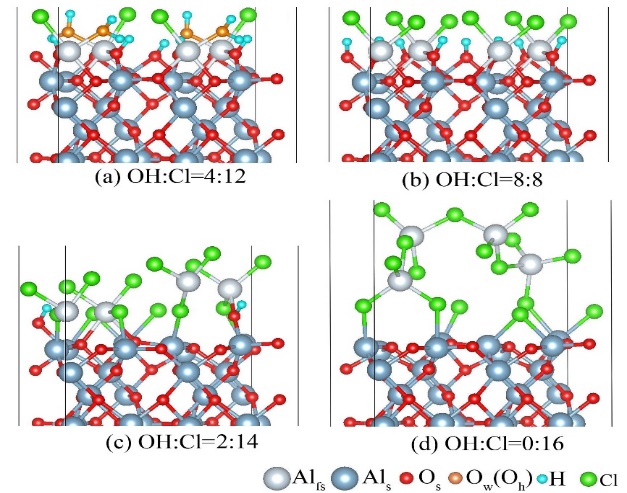

(1) Cross-scale simulation calculation of metal atmospheric corrosion

Conduct cross-scale calculation and simulation of material corrosion, analysis and modeling of corrosion electrochemical data, evaluation and prediction of pitting corrosion, application of corrosion integrated calculation, material data collection and database integrate technology.

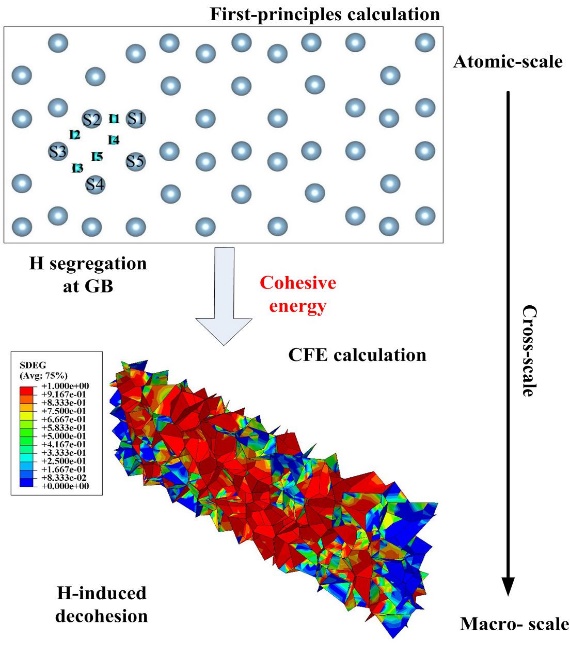

(2) New technology for indoor and outdoor correlation assessment of material environmental corrosion

The correlation analysis of indoor and outdoor results in the atmospheric environment of materials was carried out. Based on the characteristics of environmental factors in typical atmospheric environment, a new technology for accelerated corrosion test of indoor environmental spectrum in atmospheric environment was established. It lays a test and theoretical basis for the development of typical atmospheric environmental equipment service and infrastructure reliability and life assessment technology in China.

(3) New technologies for environmental corrosion and life assessment

Develop a series of new indoor corrosion evaluation technologies for atmospheric environment, and provide technical support for the reliability and life assessment of mechanical equipment materials. The patents formed by the new technology will form the basis of China's atmospheric environment corrosion indoor acceleration technology, and provide technical services for many enterprises such as transmission power grid, electronic materials, and auto parts.

【Research projects】

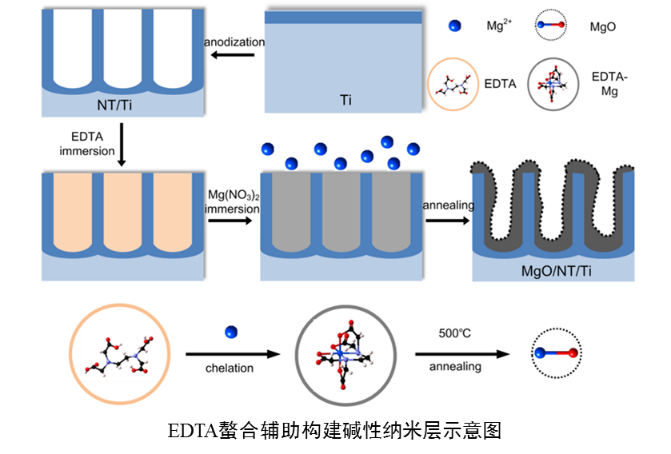

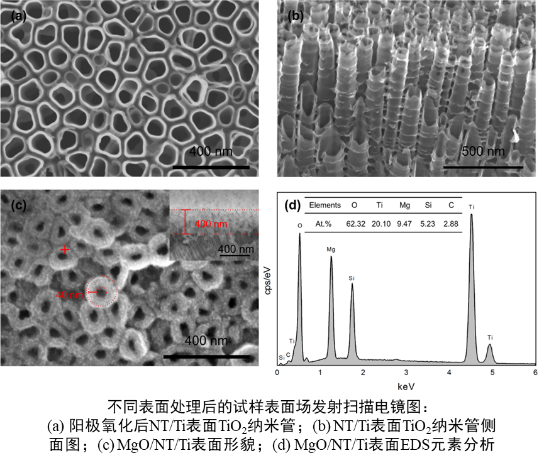

(4)Development and evaluation of new corrosion resistant materials

A series of new oral implant titanium and its surface treatment technology have been developed, and implant materials with good biocompatibility, antibacterial and corrosion resistance have been prepared.

【Research projects】

(1) National Material Environmental Corrosion Platform, Ministry of Science and Technology, to participate;

(2) Material structure-performance data acquisition and database integrate technology based on high-throughput experiments and calculations, national key research and development plan project (2017YFB0702300), responsible, 2017.7-2020.12

(3) Computational simulation and experimental study on the influence of adsorption on the structure and stability of metal passive film, National Natural Science Foundation of China (51671029), responsible, 2017.1-2020.12;

(4) Mechanism of mold and electrochemical interaction of printed circuit boards under thin liquid film, National Natural Science Foundation of China (51671027), responsible for 2017.1-2020.12;

(5) Theoretical basis and corrosion resistance mechanism of p-n junction structure passive film prepared on the surface of ferritic stainless steel, National Natural Science Foundation of China (51671028), responsible, 2017.1-2020.12;

(6) High-strength, large-size, easy-to-weld marine engineering steel and application, national key scientific research and development special project (2016YFB0300600), participation, 2016.7-2020.12;

(7) Study on the influence law and mechanism of Nb(C,N) nano precipitation on deep sea stress corrosion of X80 pipeline steel, National Natural Science Foundation of China (51471033), responsible, 2015.1-2018.12;

(8) Research on the corrosion behavior and mechanism of high-strength corrosion-resistant car body and high-speed rail bogie frame steel, national key research and development program (2017YFB0304602), participated in, 2017.11-2020.12;

(9) Evaluation of metal corrosion performance under different new thermal insulation materials (industrial project ), 0.5 million yuan;

(10) Development of countermeasures and control technology for steel corrosion, 2018, 1.48 million yuan, Nanjing iron & steel co., LTD;

(11) Correlation research between environmental spectrum and accelerated test of atmospheric corrosion in the South China Sea and marine corrosion in Qingdao sea water conditions, 2017;1.2 million, Anshan Steel Company Limited;

(12) The preparation and coating methods of passive solution for zinc coating (patent transfer), 2017, 0.15 million yuan, Tianjin xianzhibang technology co., LTD;

(13) Outdoor atmospheric exposure corrosion test of high-performance weather-resistant bridge steel, 2017, 0.48 million yuan, Nanjing iron & steel co., LTD;

(14) Research and development of corrosion-resistant reinforcement for ocean use, 2014, 0.65 million yuan, Nanjing iron & steel co., LTD;

(15) Corrosion life research of metal materials under atmospheric environment, 2014, 0.9 million yuan, Huawei technologies co., LTD;

(16) Control technology of corrosion resistance of steel surface, 2012, 0.75 million yuan, Nanjing iron & steel co., LTD;

(17) Corrosion database and corrosion life prediction project, 2012, 0.52 million yuan, Huawei technologies co., LTD;

(18) Corrosion life rapid verification technology project, 2012, 0.45 million, Huawei technologies co., LTD.

(19) Design of experimental platform for flow accelerated corrosion and water&gas loop, 2011, 1.08 million, Suzhou Thermal Engineering Research Institute Co., Ltd;

(20) Research and development of corrosion-resistant steel for crude oil cargo tank, 2011, 1.4 million, Nanjing iron & steel co., LTD;

(21) Functional expansion of naphthenic acid corrosion dynamic simulation experimental device, 2010, 0.74 million yuan, Qingdao institute of safety engineering, China petroleum and chemical corporation.