Institute of corrosion control systems engineering

Natural environment corrosion and surface protection engineering laboratory

【Faculty & Staff】

|

|||||

Xiaogang Li |

Jiquan He |

Jin Zhang |

Jiangli Cao |

Deren Wang |

Junsheng Wu |

|

|

|

|||

Hongchi Ma |

Yong Lian |

Yue Chang |

|||

Xiaogang Li Professor,Doctoral supervisor |

Jiquan He Associate professor, Master's supervisor |

Junsheng Wu Professor,Doctoral supervisor |

Jin Zhang Professor,Doctoral supervisor |

Jiangli Cao Professor,Master's supervisor |

Deren Wang Associate professor,Master's supervisor |

Hongchi Ma Assistant professor |

Yong Lian Assistant professor |

Yue Chang Assistant professor |

【Main research and Achievements】

Research direction of natural environment corrosion:

1. Developed a standardized material environmental corrosion field test station network and evaluation technology system of the new period in China

Under the joint leadership and support of the China Ministry of Science and Technology and the China Ministry of Finance, the National Material Environmental Corrosion Platform, which was established by our research laboratory, was recognized as one of the first 23 “National Science and Technology Infrastructure Platform” by the China Ministry of Science and Technology in 2011 and became a public commonweal experimental research platform and data sharing platform open to the world. Relying on the platform, we establish the new period “Natural Environment Corrosion Testing and Evaluating Systems of Materials” in China, including: ① A new period national material field environmental corrosion test platform consisting of 31 test stations, including 15 atmospheric stations, 9 soil stations and 7 water environment stations, starting from Korla in the west and Zhoushan Island in the east, north to Mohe River and south to Nansha islands, covering China's typical atmospheric, seawater and soil environmental zones; ② We establish a new system for testing and evaluation of field environmental corrosion test in China, which not only effectively improves the standardization of natural environment corrosion test in China, but also makes up for international deficiencies, such as the dry heat atmospheric exposure test field in Turpan and its evaluation procedures, which make up the deficiencies of the lack of dry heat and atmospheric corrosion tests and procedures in the world. ③ We developed a series of new indoor accelerated corrosion techniques based on the consistency of indoor and outdoor corrosion mechanisms in the atmosphere, soil and marine environment. The established series of techniques for accelerating corrosion spectrum in harsh atmospheric and marine environments, saline and acid soils has become the most important component of the material environmental corrosion assessment technology system. In the past five years, the construction and operation services of our platform have achieved remarkable results, providing comprehensive support services for the construction and operation of large-scale projects including island reef construction, large-scale water conservancy and hydropower projects, cross-sea bridges, and nuclear power projects. Through long-term systematic material environmental corrosion tests and data accumulation, it has made significant contributions to the selection of key materials and life evaluation of major national science and technology projects such as “large-scale aircraft”, “manned aerospace and lunar exploration projects”. The National Material Environmental Corrosion Platform has become a world’s advanced level of material corrosion field observation research test site and data sharing platform.

National Material Environmental Corrosion Platform Field Test Stations,

Notice of the Ministry of Science and Technology and the Ministry of Finance

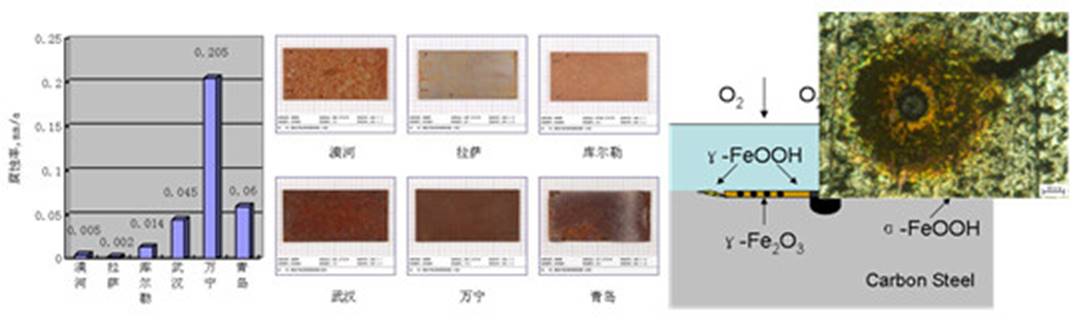

2. Study on the Law and Mechanism of Atmospheric Environment Corrosion of Materials

Atmospheric corrosion involves chemical, electrochemical, and physical processes occurring between the gas phase, liquid phase, and solid phase interfaces, and is very complex. The National Material Environmental Corrosion Field Scientific Observation and Research Platform have accumulated long-term corrosion data of 19 kinds of ferrous metals and 29 non-ferrous metals in 13 typical atmospheric environments in China. We published more than 50 papers in journals such as Corrosion Science and more than 10 sets of serialized atmospheric corrosion evaluation methods, e.g., the patent “a kind of trace corrosive gas environmental test chamber” and equipments were also developed. Furthermore, we published four monographs, including the “Initial Behavior and Mechanism of Metal Atmospheric Corrosion” and obtained the second prize of National Science and Technology Progress Award in 2009.

Atmospheric Corrosion Behavior and Mechanism

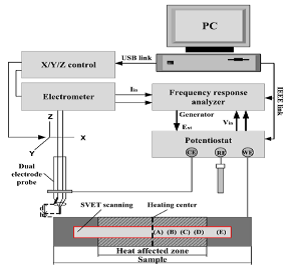

3. Research on Corrosion Evaluation and Protection Technology of Material in Marine Environment

Targeting materials urgent needs in the field of marine corrosion and protection, around the field test - data accumulation - mechanism law - standard setting - protection technology - sharing - engineering applications etc., the full-chain research system unique to the discipline of corrosion and protection, through long-term basic research and public commonweal services, based on the national marine corrosion test platform, we systemic clarifies the law and mechanism of marine environmental corrosion failure in China, and establishes a new system for material marine environmental corrosion assessment and protection technology in China, which effectively improves the safety and service life of major marine engineering and equipment. It has realized a series of innovations in marine environmental corrosion assessment technology. The basic research and comprehensive protection technology of marine corrosion have been widely used in more than 30 offshore platforms including the Liwan 3-1 and offshore equipment, aerospace, ships, and weapon type. We has obtained more than 10 patents, published more than 50 peer review papers, 3 monographs on marine corrosion, and won the second prize of National Science and Technology Progress Award in 2016.

R & D series of new technologies for marine corrosion indoor and outdoor testing

4. Corrosion big data and computational simulation research

Based on the long-term field test results of national material environmental corrosion platform, a large amount of material environmental corrosion data has been accumulated, and the material corrosion database with the largest amount of data and the most abundant content has been built, and we establish a national-level corrosion data sharing service platform. We also put forward the scientific concept “corrosion big data”, and establish a new mode of high-throughput wireless acquisition, processing and sharing of corrosion data. Also, we developed a series of large-scale corrosion data mining methods, and clarified the new understanding of the environmental corrosion mechanism of some materials, multi-scale simulation and simulation of corrosion morphology evolution dynamics, which display useful exploration and demonstration for the research of material corrosion genomic engineering. Furthermore, we develop a big data mining model for material corrosion life and applied to equipment life assessment projects in the fields of power, pipeline and petrochemical industry. We published the first monograph on "Material Corrosion Informatics" at home and abroad, and published a review research paper in the Nature with the theme of "corrosion data share", which systemic put forward the concept of "corrosion big data" and its theoretical framework and technical model. The research results“Innovation and Engineering application of Material Environmental Corrosion Data Information System” won the first prize of Science and Technology Progress Award of China Society for Corrosion and Protection in 2015, the first prize of Science and Technology Progress Award of the Ministry of Education in 2016 and the Outstanding Institution Award of National Association of Corrosion Engineers in 2015.

Material environmental corrosion data information sharing system

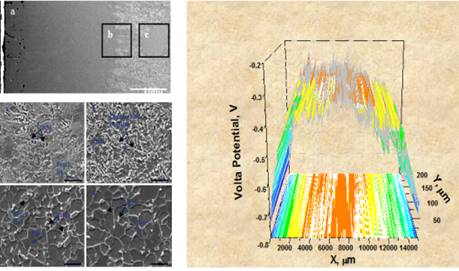

5. Development and evaluation of new corrosion-resistant structural steel

Based on the long-term corrosion test of the marine environment for 16 years, the macroscopic influence of the alloying elements and content on the corrosion behavior of low alloy steel was found. It is the first time in the world to systematically study the electrochemical mechanism of low-alloy steel matrix structure, phase structure and welded structure under severe corrosive environment (tropical ocean and acidic medium) by using advanced micro-zone electrochemical technology. We obtained the localized corrosion mechanisms induced by micro-scale inclusions and nano-scale precipitation phases and the metallurgical factors, environmental factors that affect them. The research results have published more than 30 peer review papers in famous journals such as Corrosion Science. Based on the micro-zone corrosion electrochemical technology of inclusions and new regulation technology of micro-nano-scale microstructure, the design idea of rare earth element control micro-scale composite inclusions in low alloy corrosion-resistant steel is proposed. It has been confirmed that the sensitivity to hydrogen embrittlement and corrosion fatigue of steel can be effectively reduced by improving the size of inclusions or precipitated phases in steel. Based on the above-mentioned mechanism research and innovation, the key production process control technologies such as inclusion control, plate type control and corrosion resistance evaluation were formed, and Q415NH-BH coastal area paint-free corrosion-resistant structural steel with independent intellectual property rights was invented. Also, a series of new marine engineering steels such as 690MPa grade ultra-high strength steel plate and HRB500 grade corrosion resistant steel bar have been developed, which solved the problem of corrosion welding of marine engineering steel in severe marine environment. The new series of corrosion-resistant structural steels produced by Nanjing and Anshan Iron and Steel Co., Ltd. have formed an industrial scale. Some varieties have broken the monopoly of foreign steel companies and have been applied to national key projects such as sea-crossing bridges, coastal buildings and undersea tunnels. Some of them have also been successfully exported. The research results won the first prize of the 2017 Jiangsu Science and Technology Progress Award, and Professor Li Xiaogang won the “Outstanding Technology Contribution Award” of National Association of Corrosion Engineers in 2017.

The combination of microstructural simulation and micro-zone scanning electrochemical technology solves the difficulties in electrochemical research of steel materials

Research on surface protection engineering

1. Surface modification and coating preparation technology of Titanium alloys

Titanium alloys have been highly valued and widely used in aviation, aerospace, marine, petroleum, chemical, weapon, electronics and other industries due to their excellent comprehensive mechanical properties. The surface modification and coating, i.e., micro-arc anodic oxidation, ion nitridation, cathodic plasma treatment, and thermal oxidation processes were selected to improve the wear resistance, oxidation resistance and self-cleaning properties of titanium alloy substrates. More than 10 peer review papers have been published in domestic and foreign journals such as Surface and Coatings Technology.

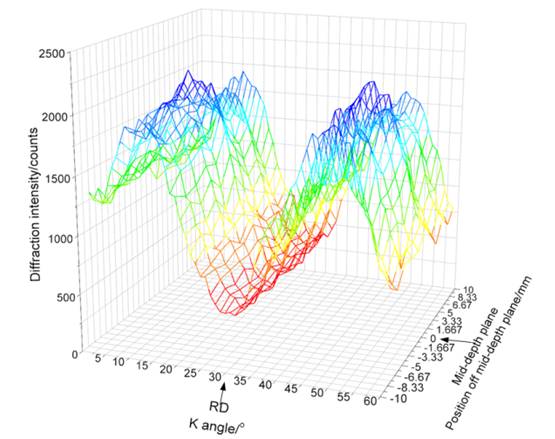

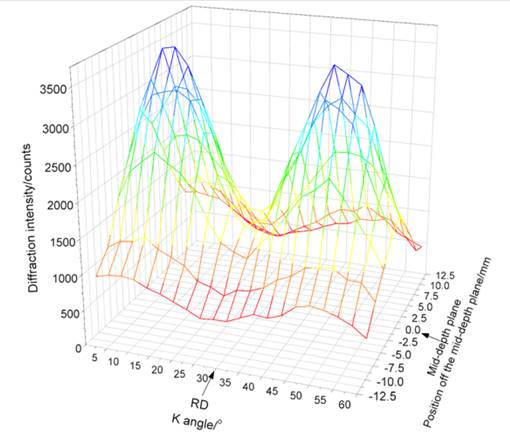

2. Residual Stress Characterization and Reduction Control Technology

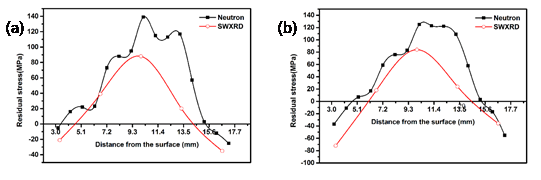

The tungsten target short-wavelength characteristic X-ray diffraction technique (SWXRD) is used to realize the fixed-point non-destructive testing of the internal texture and residual stress of the material and the non-destructive fixed-point test can be realized with the maximum thickness of magnesium alloy (70 mm), aluminum alloy (40 mm) and titanium alloy (9 mm).The relevant test results are consistent with the neutron diffraction test results. With two-dimensional surface-inspection surface stress tester, it can quickly measure surface residual stress. For the measured residual stress distribution, it can provide residual stress reduction and homogenization scheme, which provides a solid foundation for high-precision manufacturing and high-precision instrumentation. The research has been supported by the National Science and Technology Ministry's 863 Program, the National Natural Science Foundation and the Ministry of Science and Technology Key Research and Development Program and the development of large-scale scientific instruments and equipment. The relevant testing techniques and methods are leading at home and abroad. Relevant academic achievements were published in domestic and foreign journals such as Journal of Materials Science.

|

|

SWXRD得到的两种不同铝合金板沿板厚织构分布比较

中子衍射和SWXRD测得的铝合金淬火板内部(a) TD和(b) RD方向残余应力分布对比

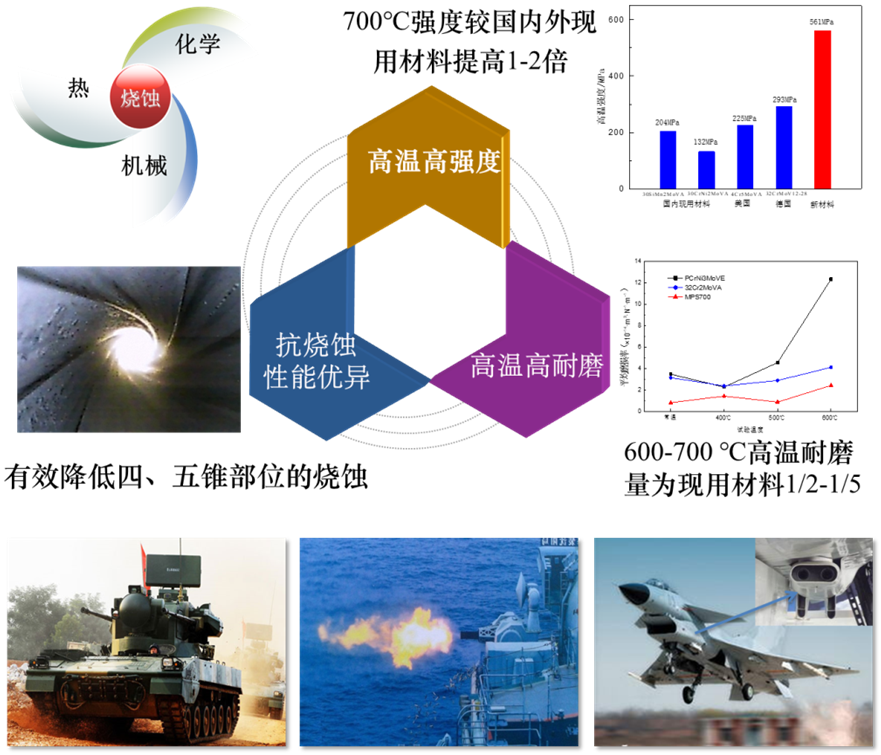

3. Long-life heat- and wear-resistant steel body tube technology

The body tube is the core component of the rapid-fire weapon, and it is subjected to high-temperature, high-pressure, high-speed corrosive gunpowder ablation and erosion, alternating load extrusion and wear and tear. Aim at this working conditions, low-carbon and multi-component composite alloying is used to achieve a variety of multi-scale and multi-scale stable carbides in a wide temperature range. The high temperature strength of the new material is 1.5~2 times of the same material, and the high temperature wear of 600~700°C is 1/5~1/2 of the current material. The material has been popularized and applied in some types.

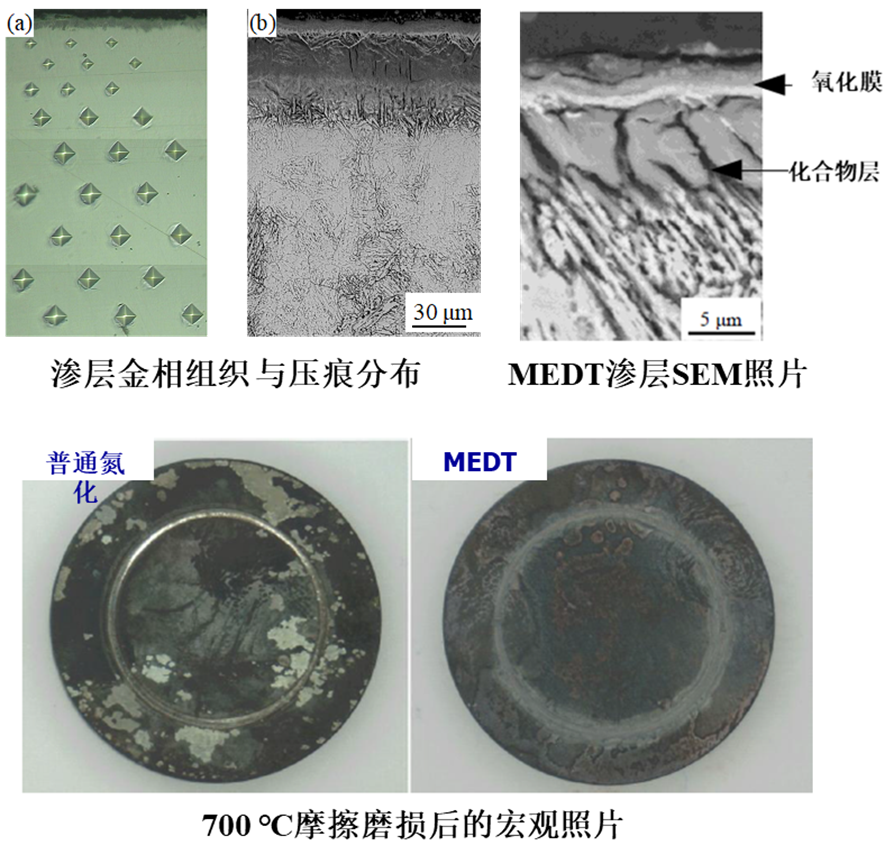

4. Multi-component composite coating with wear-resistant corrosion-resistant

Surface multi-composite modification treatment is realized by metal cementation with multiple active elements such as N, C, O, B, RE, etc., which significantly improves the wear resistance at room temperature and high temperature. A wear-resistant layer is formed at the same time, a dense oxide film can be formed on the surface of the layer to improve corrosion resistance.

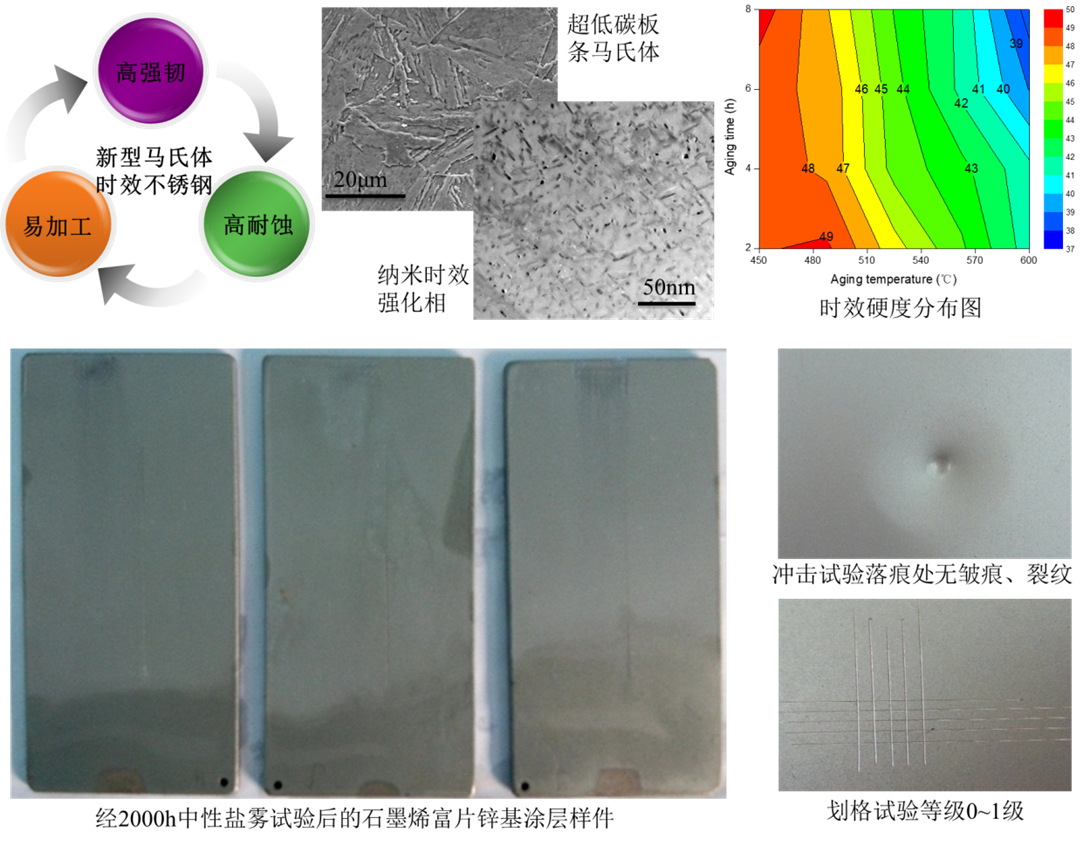

5. Marine corrosion resistant high strength steel and coating protection

A new type of maraging stainless steel with strength of 1800 MPa and excellent toughness and excellent corrosion resistance was developed, and a reasonable heat treatment specification was established. The nano-layered graphene was applied to a rich zinc-based coating to form a nano-micron layered conjugated long-lasting corrosion-resistant coating, and the neutral salt spray resistance test was over 2000 h. We obtained 2 patents and the relevant research results have been published in Mater. Sci. Eng. A and other journals

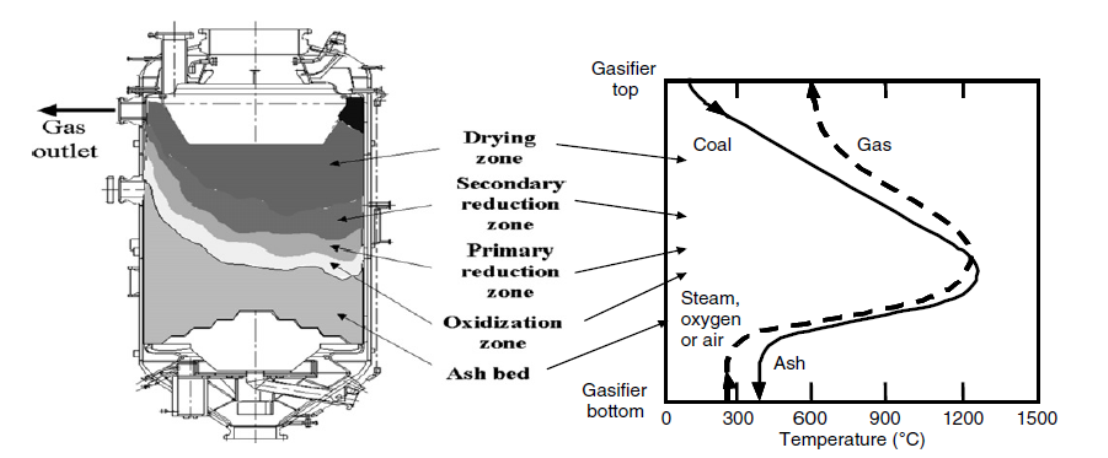

6. Corrosion mechanism and protection technology of coal chemical equipment

During the operation of the gasifier, the jacket may undergo complex corrosion types such as oxidation, vulcanization, carbonization, vulcanization-oxidation corrosion, peeling corrosion, and abrasion-corrosion. If not properly controlled, most types of corrosion can cause large losses in the jacketed metal material, causing the type of corrosion to turn into catastrophic loss corrosion. To this end, a comprehensive study of various types of metal materials, such as: 800, 601, 310, RA-333, LM-1866, 446, 671, CRUTEMP 25, 188, Co-Cr-W, alloy 28, 310Nb, 304, HR 160 in simulated gasifier environment, the results provide reliable test data and technical support for gasifier anti-corrosion and longevity.

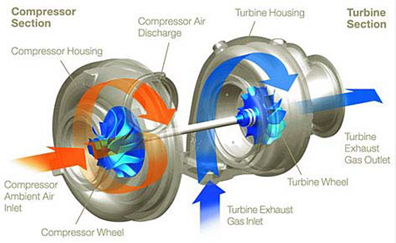

7. Preparation technology of automobile exhaust catalytic coating

In cooperation with Ford Motor Company's automotive Turbine Ceramic Coating URP project, the use of cathodic plasma electrolytic deposition technology to prepare active alumina coating on the surface of automotive turbines has made breakthroughs in the stage. The application of this technology will effectively change the phenomenon of non-catalytic ability during the traditional three-way catalytic incubation period, greatly reduce the pollutant emissions during the cold start of the automobile, and meet the increasingly strict vehicle exhaust emission standards. The cathodic plasma electrolytic deposition technology has the characteristics of controllable microstructure of the coating, adjustable phase composition, large surface area of the coating, and no limitation on the shape of the work piece. It can perform plasma deposition on the complex shaped work piece to in-situ form the oxide ceramic, which is ideal for automotive turbine catalyst carrier coatings.

8. 8, Hydrogen isotope-related behavior in typical oxides of anti-deuterium barrier coatings and synchrotron radiation of ferroelectric thin films

The research work of fusion stack barrier coating has become one of the frontier areas of fusion science and technology in the world. Research topic: 1) the existing form and location of hydrogen isotopes in typical oxide materials coated with tritium resistance were studied by means of energy spectrum, spectrum, X-ray diffraction and structural refinement, or secondary ion mass spectrometry. 2) Study on the influence of hydrogen isotope on the structure, mechanical and electrical properties of tritiated coating oxide materials. It is of great significance to study the material selection, structure design, preparation and service reliability of the tritium coating for the controlled thermonuclear reactor. The integrated ferroelectric components with ferroelectric thin films have important application prospects in computer information storage and data processing. However, its actual progress is greatly limited by basic problems such as interface research, size effect and ferroelectric fatigue. This project utilizes the advantages of synchrotron radiation technology to carry out research in the field of ferroelectric thin film.

【Research projects】

· 1, Project 973: Fundamental research on key technologies of corrosion and protection of marine engineering equipment materials, 28 million yuan, 2014-2018;

· 2, Project of Ministry of Science and Technology: National field scientific observation and research platform for environmental corrosion of materials (2012-present), the funding is about 20 million yuan per/year;

· 3, Project of Ministry of Science and Technology: Investigation on the current situation of material corrosion in China and the pollution of natural environment caused by material corrosion, 9.19 million, 2012-2016;

· 4, 863 project: Study on corrosion evaluation method of high strength steel for oil and gas pipelines in typical acidic and alkaline soil environment; 760,000 yuan, 2012-2014;

· 5, National natural science foundation of China: Stress corrosion behavior and mechanism of 690 alloy heat pipe used in pressurized water reactor nuclear power plant steam generator, 2.4 million, 2012-2016;

· 6, National natural science foundation of China: Research on key influencing factors and mechanism of soil corrosion of high-strength pipeline steel, 3 million, 2011;

· 7, National natural science foundation of China: Characteristics of microenvironment and local corrosion damage mechanism of Marine fouling biological adhesion gap in stainless steel, 620, 000 yuan, 2018-2021;

· 8, Key projects of the Ministry of Science and Technology: Residual stress reduction and surface protection of magnesium alloy products, 1.8 million yuan, 2017-2020;

· 9, Bottleneck technology project of General Equipment Unit of PLA: 7.5 million yuan, integrated manufacturing technology of anti-ablation XX body tube and anti-corrosion structural parts, 2015-2018;

· 10, Final assembly bottleneck technology project: 2.5 million, XXXX extended life technology, 2015-2018;

· 11, Major defense basic scientific research projects: 3.6 million yuan, XX efficient and accurate manufacturing technology, 2017-2020;

· 12, Project collaborated with Beijing education commission: Research on solution plasma micro-arc electrodeposition composite coating technology, 300,000 yuan, 2017-2018;

· 13, International cooperation project: study on cathodic micro-arc plasma electro-deposition of ceramic coating on nickel-based alloy turbine blade and stainless steel guide blade, $100,000, 2016-2017;

· 14, National ITER plan: research on hydrogen isotope-related behavior of typical oxide in tritiated coating, 100,000, 2011-2013;

· 15, National natural science foundation of China: research on synchrotron radiation of ferroelectric thin films, 360,000, 2010-2012.

【Research team construction】

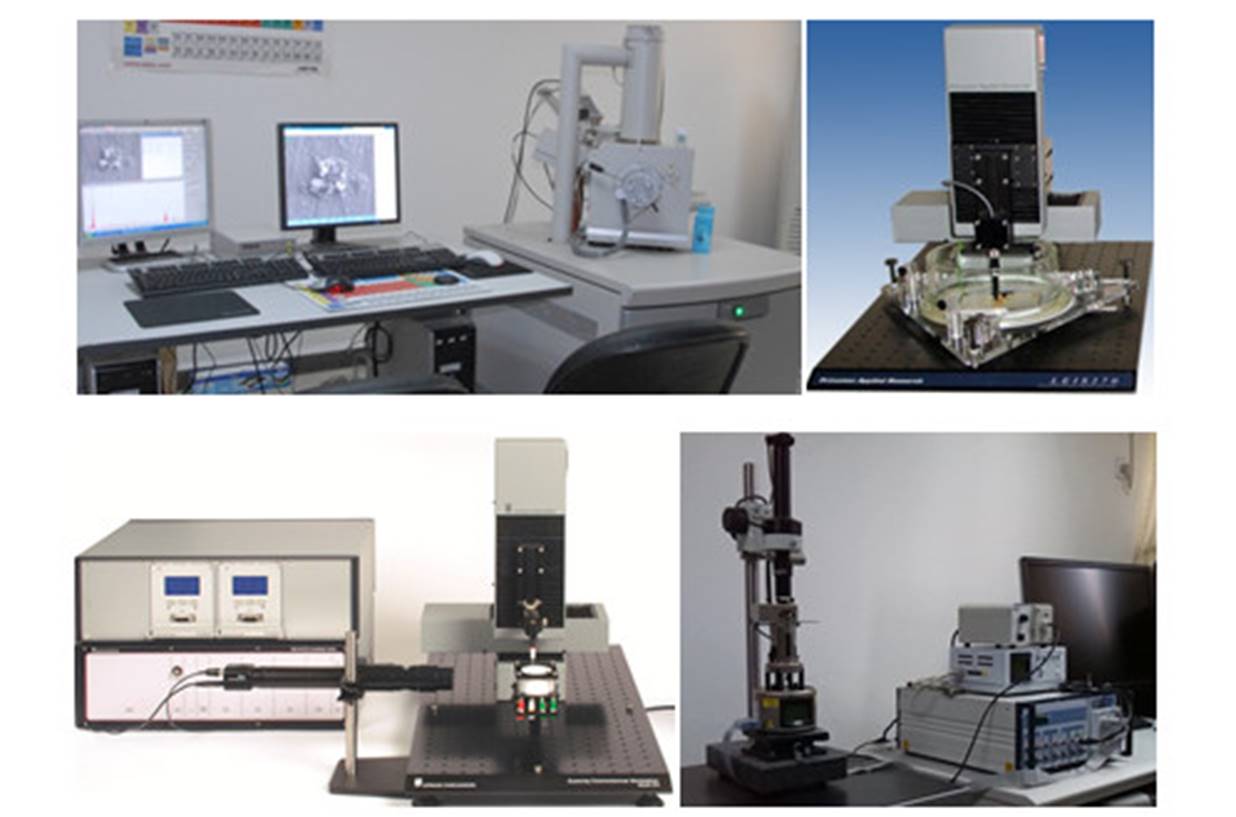

Natural environment corrosion and surface protection engineering laboratory is a big family of unity, fraternity and harmony, there are 18 doctoral candidates and 65 master candidates. More than 40 Ph.D. students and more than 100 master's students have graduated from here. The laboratory invested more than 15 million yuan in all kinds of equipment. The team has scanning electron microscope, atomic force microscope, micro-area electrochemical work-station, 3D confocal microscope, salt spray chamber, ultraviolet aging chamber, dry and wet weekly immersion and soil acceleration test chamber, fatigue, high pressure and slow pull up testing machine, a variety of high pressure corrosion test equipment and other large test and testing equipment.

The research lab has a good academic atmosphere and scientific research environment. Members of the research lab have the opportunity to attend domestic and foreign academic conferences and scientific research activities from time to time, and can participate in a large number of enterprise-related topics to improve their practical ability. In scientific research and study, the members of the research office are active and diligent. Classmates unite and love each other in their daily life. In addition to study and research, the research lab also has a variety of group activities: such as holiday dinner, spring outing, badminton and basketball games, etc.