Laboratory of failure analysis

Laboratory of environmental fracture

【Laboratory Overview】

Research on environmental fracture focuses on macro and micro mechanisms for materials in various environments.Laboratory for Environmental Fracture is one of the pioneering laboratories to study stress corrosion cracking. In 1980’s, academician Xiao Jimei, famous metallurgy and materials scientist led the research on the stress corrosion cracking of aircraft landing gears. Since then, the research on stress corrosion cracking and hydrogen embrittlement has been developed rapidly. After decades of development, the laboratory has become one of the most influential lab on environmental fracture globally.

The main research areas in the laboratory are:

1) fracture and environmental fracture of metals and alloys

2) Research and development of functional materials and multifields coupling

3) Mechanics of nanomaterials and environment effect

4) Materials Genome Engineering for anti-corrosion and anti-environmental fracture materials development

5) Safety of biomaterials

Recently, the laboratory has been awarded with major grants,such as 973, 863, NSFC from the government and from industries. Work has also been done for rockets, missile engines, space shuttles (tiangong series).

4 full-time faculties are in the laboratory, including 2 professors and 2 associate professors. Alumni from the lab over the past 40 years are working in top-ranking universities, research institutes, and major cooperates and companies, among which academician Zhang Tongyi is one of the representatives.

The laboratory has been awarded one second-prize State Natural Science Award and several awards from the province level. Over 500 papers and 20 books have been published.

【Faculty profile】

|

|

|

|

Yanjing Su |

Yu Yan |

Haiyou Huang |

Lei Gao |

Yu Yan professor, Ph.D supervisorYanjing Su professor, Ph.D supervisor

Haiyou Huang Associate professor, master students supervisor

Lei Gao Associate professor, master students supervisor

【Research activities and outcomes】

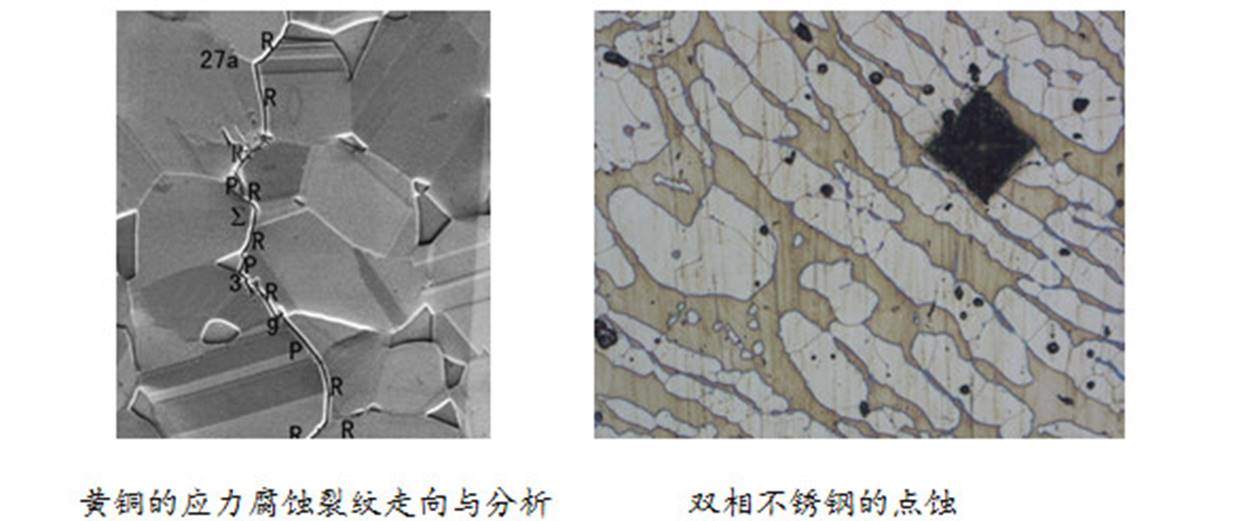

1、Fracture and Environmental Fracture of metals

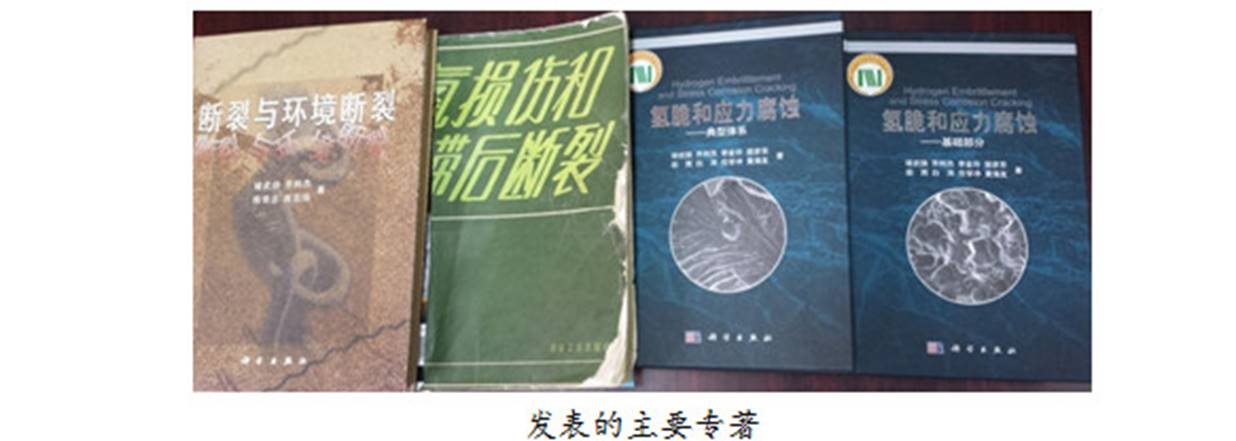

1 hydrogen and stress corrosion cracking

Environmental fracture (hydrogen embrittlement, stress corrosion cracking) is the main reason for major engineering failure. Based on our research on hydrogen embrittlement and stress corrosion cracking, more than 500 papers have been published. Books, “Hydrogen embrittlement and stress corrosion cracking” ,“Fracture and environmental fracture”, etc. have also been published. The laboratory has been awarded one second-prize State Natural Science Award (to date, the only one in the field of corrosion) and several awards from the province level.

2) Mechanisms of fracture and environmental fracture

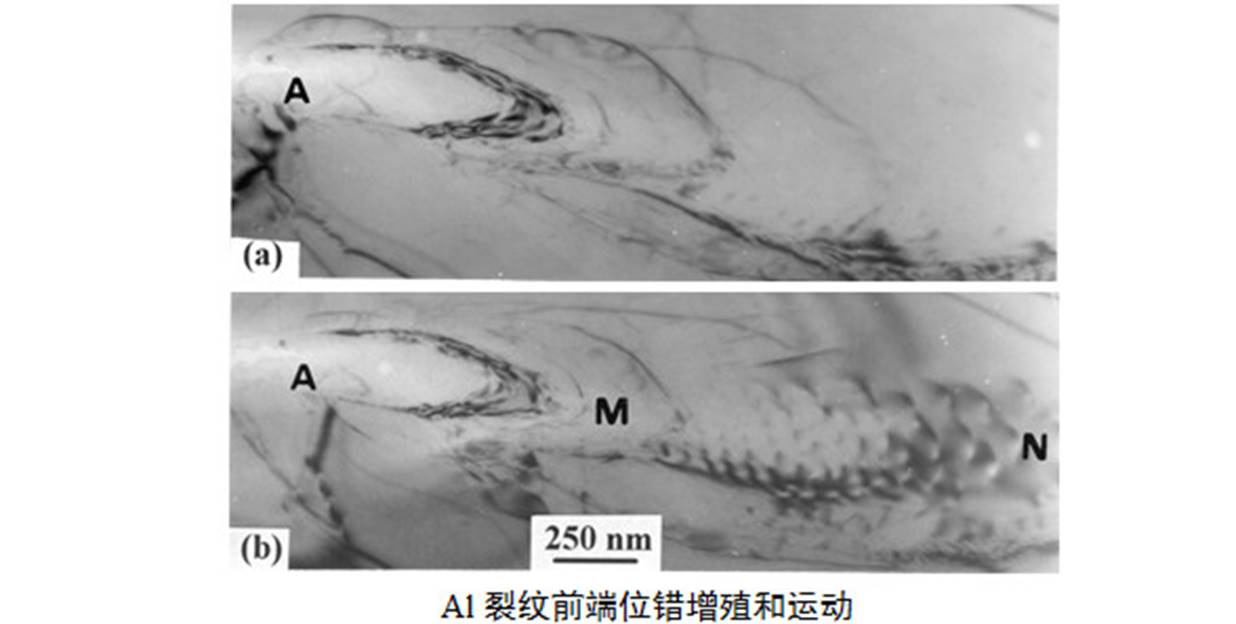

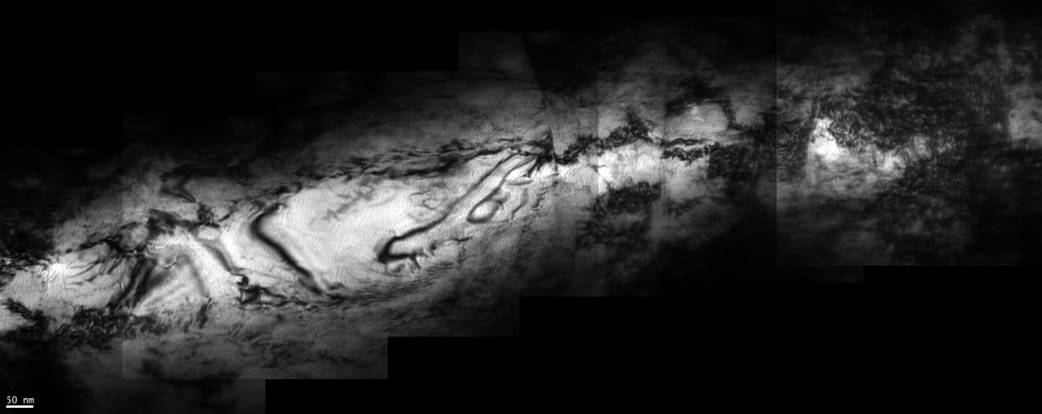

By using TEM tensile tests, the fracture process in micro level for ductile materials (Al, Cu, stainless steels,etc.) and brittle materials (TiAl and Ni3Al intermetallic) was studied. For the first time, micro cracks initiated and propagated at the tip and the DFZ zone was realized. It was found that dislocation emitted at the crack tip for both ductile and brittle materials.

Corrosive environment, hydrogen and liquid metals can all result in the emission, multiplication and movement of dislocations. While the emission, multiplication and movement of dislocations reaches the threshold status, micro cracks can then nucleate and propagate. Results were published on Acta Mater., Script Mater and other journals.

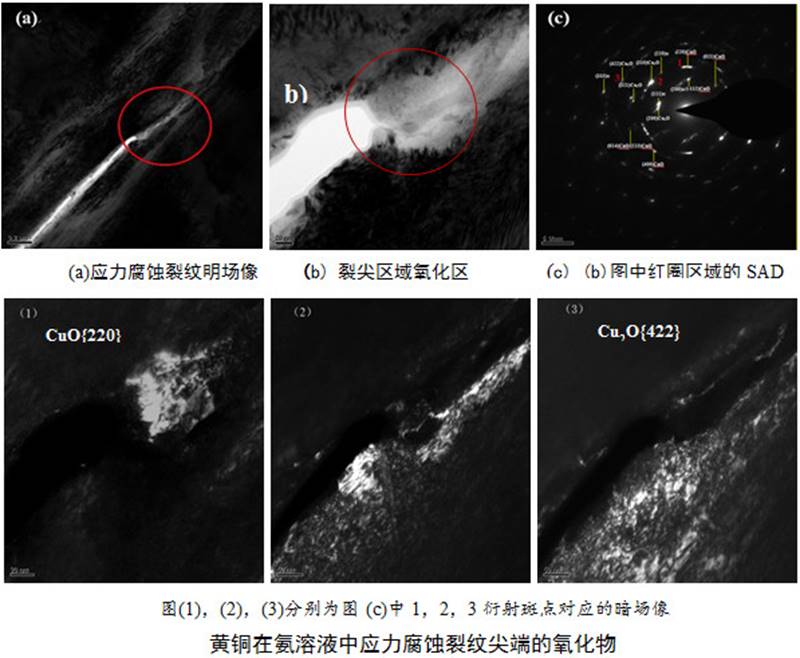

3) The relationship of Corrosion product film and SCC

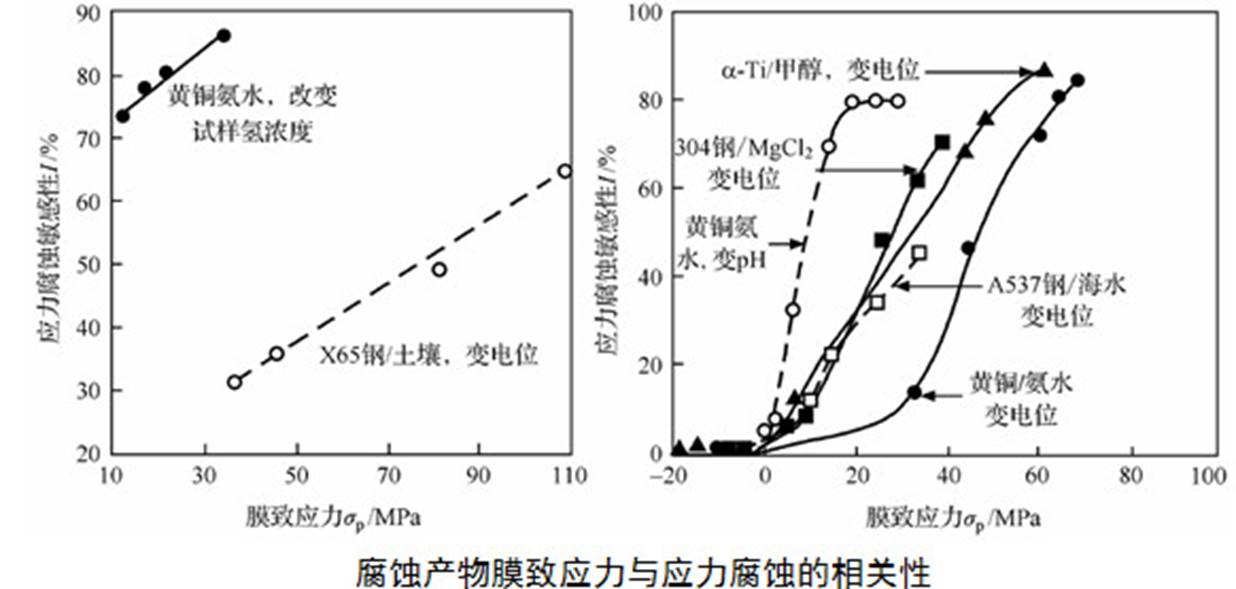

Stress corrosion cracking (SCC) can result in a formation of corrosion product at the crack tip. During the progress of the product film, a tensile stress can exist at the substrate metal. A lot of research have shown that there is a clear relationship between the sensitivities of SCC and the film-induced stress. Greater the film-induced stress, greater the SCC sensitivities are. If the film-induced stress is compress stress or zero, SCC is not present.

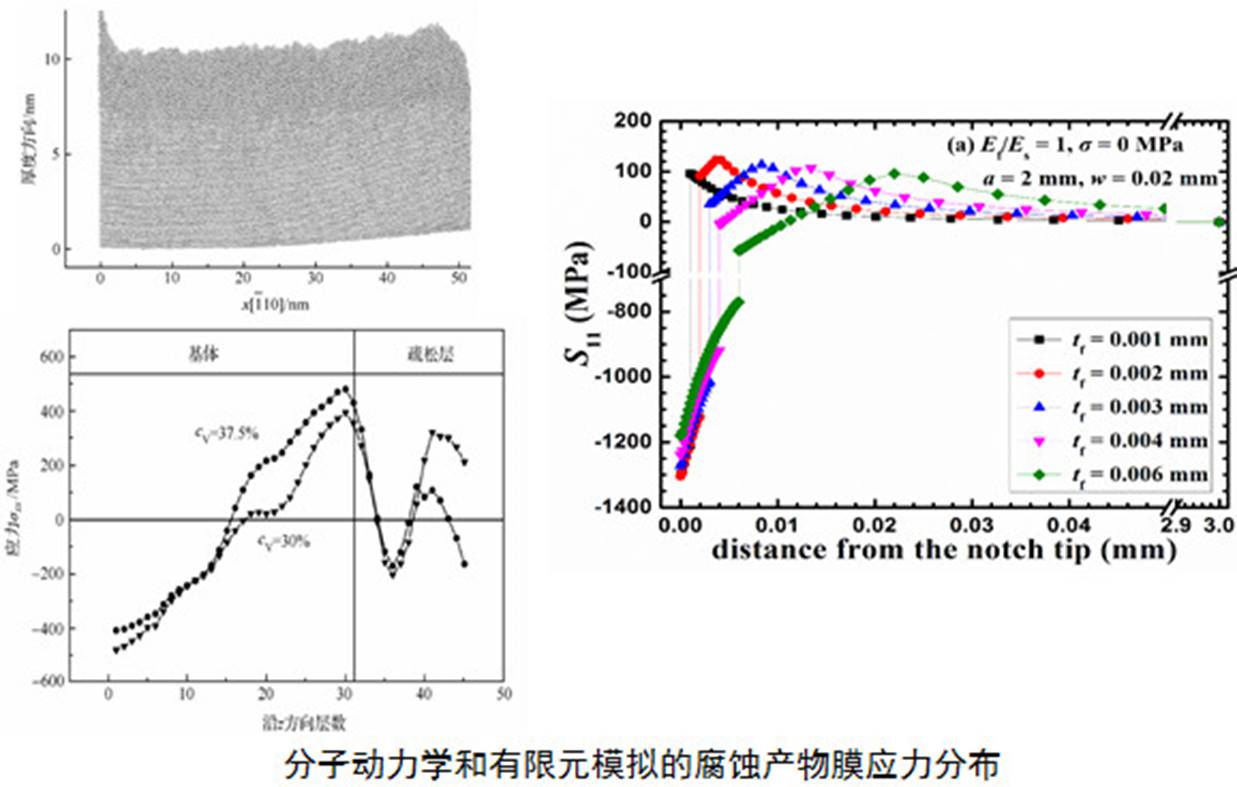

Molecular dynamics (MD) and finite element (FE) methods show that at the interface of the film and the substrate, the film-induced stress reaches it greatest level. The combination of the film induced stress and the applied stress externally can cause the emission of dislocations at the crack tip. When the threshold status is reached, SCC cracks can nucleate and propagate. Results were published on journals such as Corros. Sci. and Corrosion.

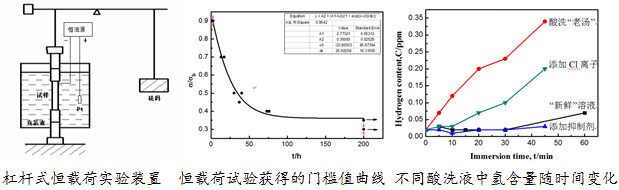

4) Delayed cracking evaluation - hydrogen embrittlement behaviour

The greater the fracture strength, the higher the hydrogen embrittlement sensitivity is. However, the main issue for the development of automotive used high strength steels is the lack of a reliable and acceptable evaluation method. It is very important to adapt a more accurate, higher efficient method for hydrogen embrittlement.

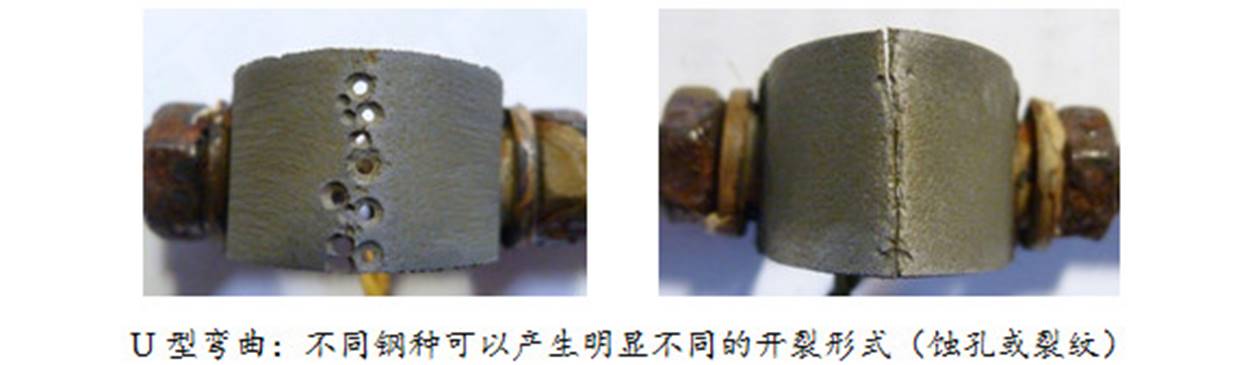

We have tested steels with strength of 980 MPa,1180MPa and 1300MPa. By using U-bend, constant loading, slow strain rate tester etc.. with hydrogen detection methods, we have investigated the sensitivity of such steels to hydrogen embrittlement. It has shown that for U-bend samples, although pits developed, but fracture did not occur. For some steels, fracture occurred with no corrosion presented. After constant loading tests, results show that all tested high strength steels show some degree of delayed cracking. The evaluation method developed by the lab has been adapted by major automotive steel manufacturer.

5) Delayed cracking mechanisms for high strength and high ductility medium Mn steels used in automotives

With the fast development of automotives, problems of energy loss and pollution have gain more attention. Lightweight strategy is one of effective ways to save energy. It requires steels to have high strength and high ductility to adsorb impact energy. Medium Mn steels compost with 5% to 10% Mn content, which is considered as the third generation materials used in automotives. In 2015, Bao steel cooperation produced the first batch medium Mn steel sheet. However, the higher the strength, the higher the sensitivity of delayed cracking is. For medium Mn steels, their high ductility (over 40%) and ultrafine grains may be a solution to solve the problem of high sensitivity to hydrogen embrittlement for high strength steels.

2、 Mechanics and environment effect for nano materials

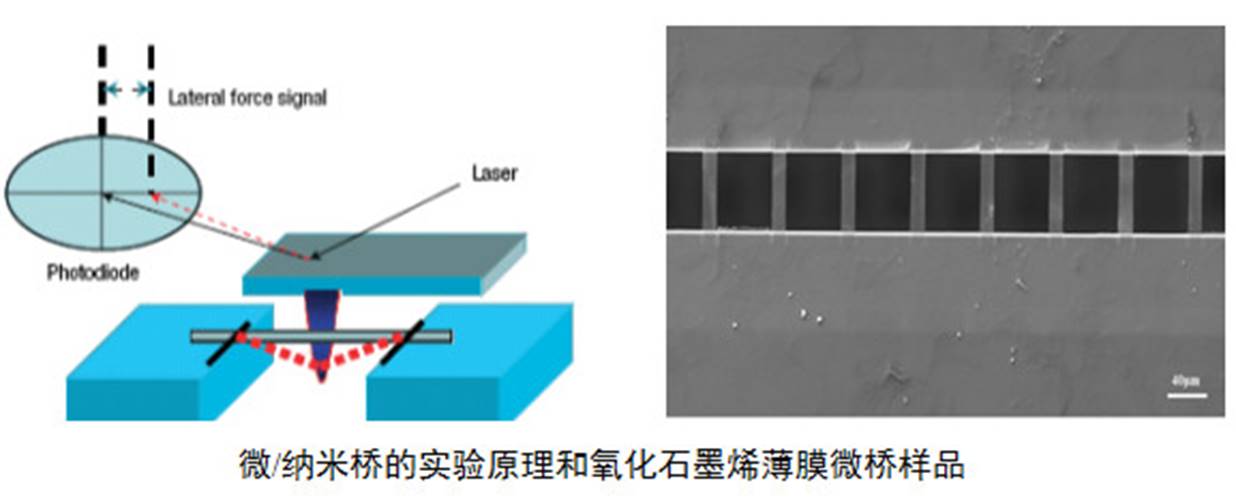

1) Mechanics for micro/nano bridge of nano materials

Based on micro/nano bridge testing theory and methods, micro/nano thin film mechanics have been developed with the collaboration with academician Zhang Tongyi. The method can test the residual stress, young’s modulus, bending strength and ductility of thin films and other parameters, which has been recognized as an effective method worldwide.

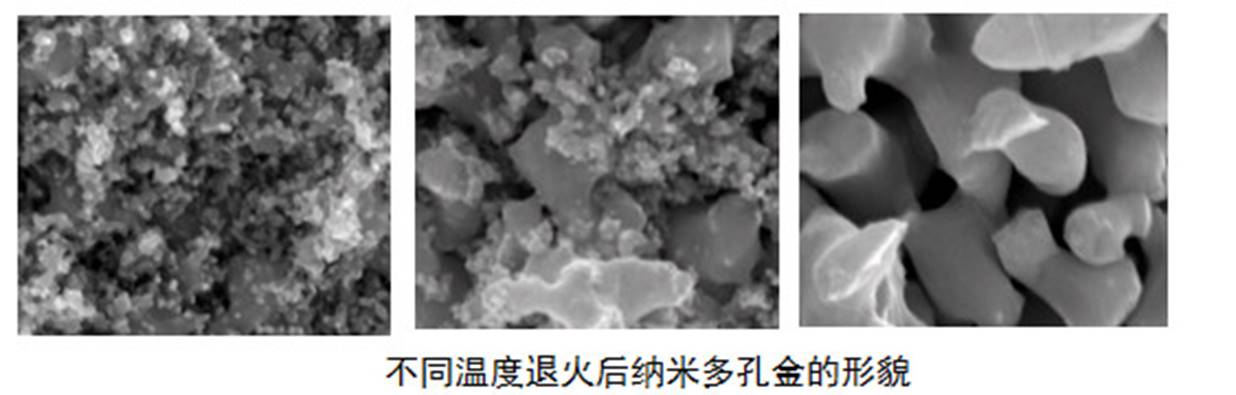

2) Electromechanical coupling effect for porous nano gold

There are many properties for nano porous gold, such as great surface area, high density of atomic steps, good electrical conductivity, surface plasma effect and high young’s modulus. It has been widely used in catalyst, electrode materials and sensors. This work was founded by NSFC/Hong Kong RGC joint project.

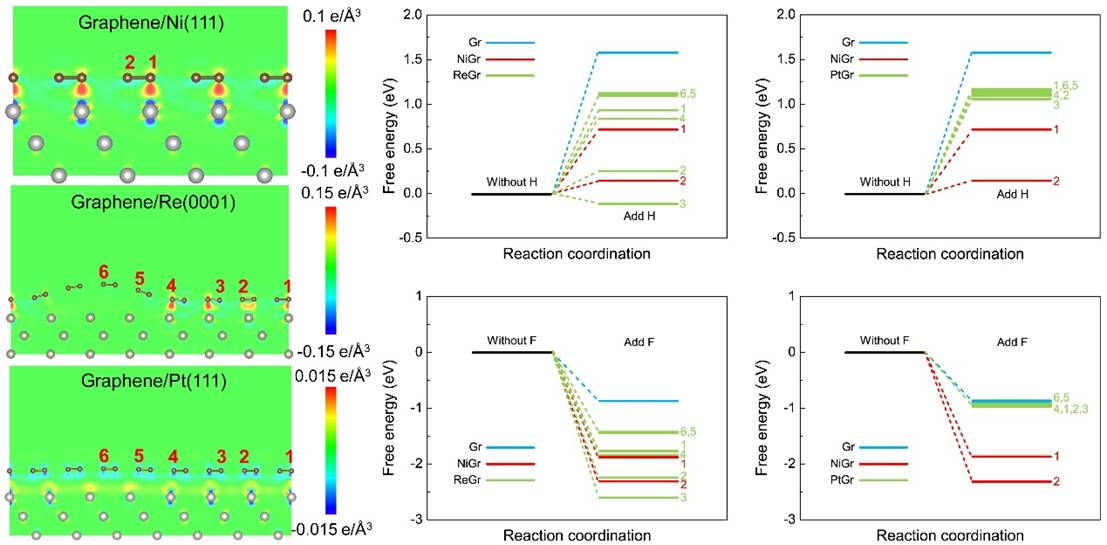

3) Tribology behaviours of 2D materials by using first principle calculation

Due to the size effect, many atoms sit at the surface and interface of devices. Forces have great influence on the application of micro/nano electronic systems, such as adsorption force and frictional force. Therefore, it is important to control and adjust frictional force for such devices.

2D materials show great potential to be candidates for micro/nano solid lubricants. Based on first principle calculation, the origin of the frictional force can be revealed. The objective for this study is to investigate the environment and the substrate effects on the surface tribological behaviours for 2D materials and design the robust and controllable solid lubricants. This work has been supported by the NSFC.

3、Materials R&D for anti corrosion and anti hydrogen embrittlement based on materials genome engineering principles

Low efficiency, complex, high cost and long period have great limit the R%D for advanced materials. To reduce the time and cost of the process, researchers worldwide have been attempted to use fusion technology for materials calculation, testing and data. On July, 2011, the US government initiated the “Materials Genome Initiation” . The core content for this initiation is to build a platform for calculation, testing and data. The key technologies are high throughput calculation, high throughput fabrication and characterization and database. The objective to greatly improve the efficiency for the R&D of advanced materials.

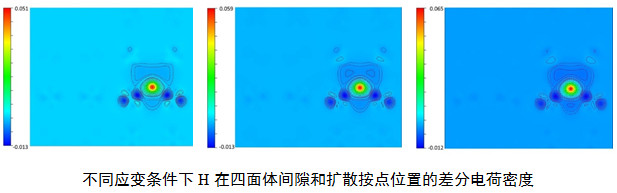

With the support from the “863”project, the role of hydrogen to enrich at the grain boundaries and weaken the grain boundaries has been revealed. The objective is by using the first principle calculation to seek advanced compounds with high hydrogen trapping sites and get high strength alloys with great anti hydrogen embrittlement property.

4、 Biocapacity for metals and alloys

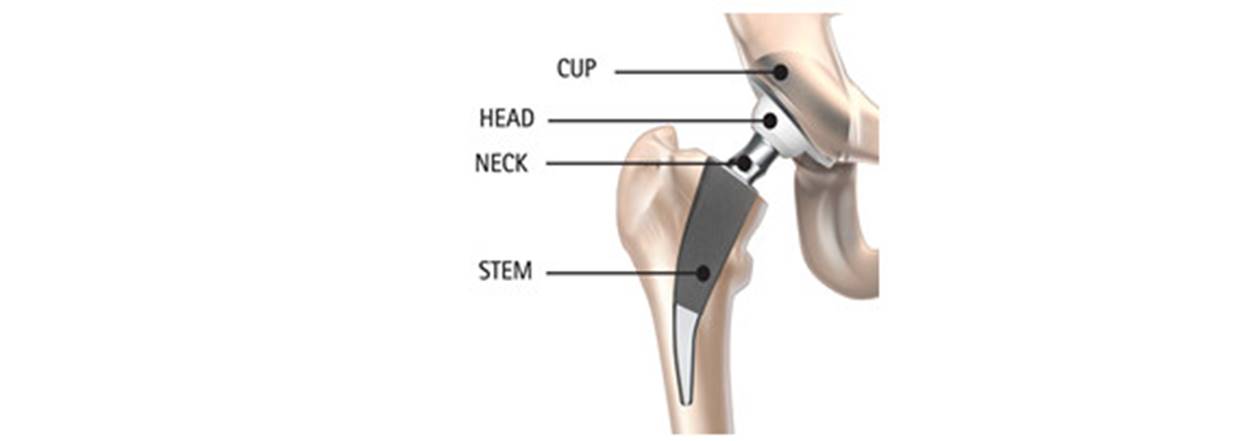

1) Interaction of tribology and corrosion for artificial joint implants

It is well know that there are interfaces with tribological contacts existed in artificial implants, which is the main reason to cause failure for such devices. In bodily environment, metal can release ions through corrosion processes. The interaction of tribology and corrosion can greatly reduce the safe of such devices. Based on our research, a thin organometallic film and a nano grains layer can be found on hip implants due to the bio-tribo-corrosion process. The complex structure can effective lubricate the rubbing surfaces and reduce material degradation. In 2011, an article published on Science cited our findings and studied the carbonatious film on the surface.

2) Surface modifications for biomaterials

As soon as a metal materials being implanted into patient, the surface can react with the surrounding environment. For some cases, we want the material degrade for a particular period of time. Mg alloys and Zn alloys are two good candidates for the application.

Another failure reason for such devices is the infection. Therefore, the question is how to improve the anti-bacteria properties at the initial implantation period.

5、Frontier research

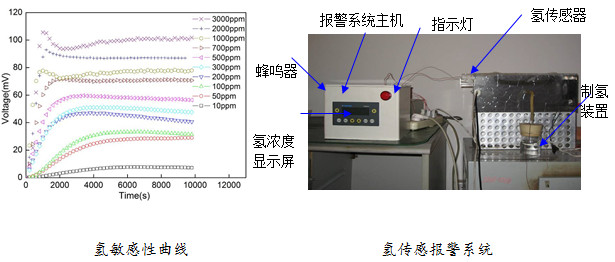

1) hydrogen sensor

Hydrogen energy is one of the promising candidates for future. Our lab has studied the hydrogen sensors based on electro potential, which show very good results.

【Major Grants】

· 1 National Key R&D project: MGE database and big data technology;

· 7 “973”projects:including Mechanisms of corrosion at various ocean environments;

· 6 “863”projects:including Research on hydrogen sensors;

· 4 NSFC key projects: Including SCC transscale study

· 32 NSFC regular projects

· 20 industrial projects

【Research facilities】

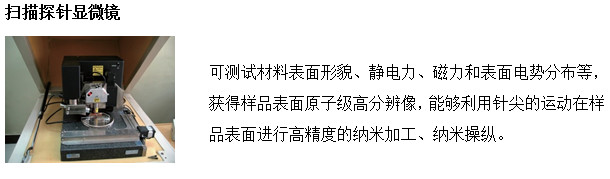

Atomic force

Nanoindentor microscope

UMT tribology tester

Ferroelectric analyzer

Magnetoelectric tester

Hydrogen tester

Fatigue and tensile tester

High performance computers

【Research collaboration】

The laboratory has wide collaborations with Carnegie Mellon University, Northwest University, Pittsburgh University, Georgia University, Oxford University, Cambridge University,University of Calgary, Alberta University, Norway University of Science and Technology, etc..

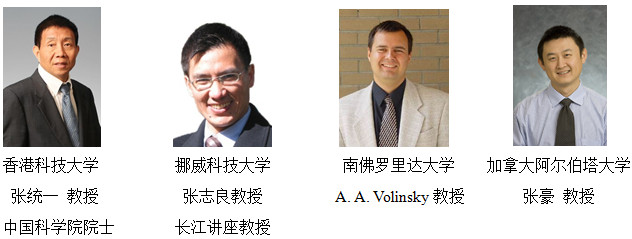

In recent years, many experts from abroad have been invited to present their work in the laboratory, including academician Zhang Tongyi from UHKST, academician Zhang Zhiliang from NUST, professor Volinsky from South Florida University etc..

The laboratory has organized many international and national conferences or seminars to build strong relationship with researchers in the field. Faculties also participated in many international and national conferences to present for keynote or invited talks.

【Team building】

The laboratory for environmental fracture is a group with enthusiasm. After graduation, students joined big companies or research institutes and some went abroad to pursue higher education.