News

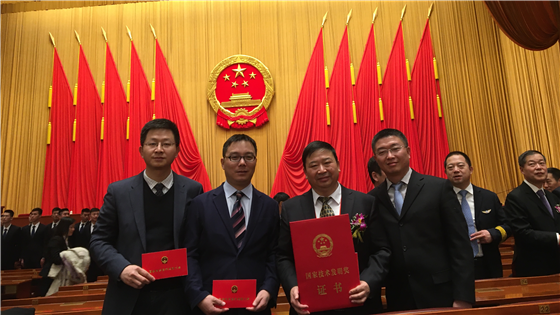

Another national award! Congratulations to the team of professor Qu Xuanhui of USTB for winning the 2019 National Technical Invention!

On January 10th, the 2019 National Science and Technology Awards Conference was grandly held in the Great Hall of the People. Professor XuanhuiQu and his team of our institute's "High-performance Special Powder Material Near-net Shape Manufacturing Technology and Application" won the second prize of National Technology Invention, which has made a good start for another glorious decade of Institute for Advanced Materials and Technology!

High-performance materials play an extremely important role in the development of high-tech fields. The technology of this project not only realizes the near-net-shape manufacturing of high-performance difficult-to-process materials, but also reaches or exceeds the advanced level of similar international technologies in terms of formability and material properties. The high-performance special material products developed by the project have been successfully used in smart phones, optical fiber communications, notebook computers, medical equipment, power tools, automobiles and other industries. The achievement completion and technology promotion and application units have become new product development partners and suppliers of well-known domestic and foreign companies such as Apple and Google.

The project has built a professional company with the highest technical level and production capacity. Among them, Jiangsu Jingyan is the only company in the world listed as a single business of powder injection molding; Shanghai Fuchi took the lead in building a high-water end injection molding automated production line; The Al-N powder production line has been constructed in Xiamen, achieving mass supply and breaking the decades-old monopoly of Tokuyama, Japan, and won the first prize of the 6th China Innovation and Entrepreneurship Competition in 2017.In addition, related technologies are also promoted and applied to more than 20 other companies. In the past three years, it has increased sales of 5.4 billion yuan, increased profits of 700 million yuan, authorized 60 invention patents, formulated 1 industry standard, published 257 papers, and trained more than 300 graduate students, whichhas contributed to China's development as the world's largest producer and seller of powder injection molding products. The related work of professor XuanhuiQu and his team has also been praised by international colleagues. Two products won the "Outstanding Innovative Product Award" at the 2018 World Powder Metallurgy Conference. The editor-in-chief of "International Powder Injection Molding Magazine" personally wrote articles for three consecutive years, and conducted special reports and recommendations on project results.

Through more than ten years of hard work, professor Xuanhui Qu and his team have created a new principle and new method of near-net shape manufacturing of special powder materials with completely independent intellectual property rights, leading and promoting the formation and development of our country's powder injection molding industry. As society pays more and more attention to resources and the environment, this technology is bound to be more widely used.